ITS Becoming the Norm

AWP Engineering Services Employ Technology for Safety’s Sake

The Texas Department of Transportation is investing billions in the I-10 corridor, the primary artery for gulf travel, as well as the massive North/South corridor IH-35.

AWP has helped design data collection and display points along multiple parts of the routes under construction. In Waco, for example, 8 display compile and show information from 42 data collection points. While some in the industry use more generalized data, thanks to internally-generated algorithms, AWP’s displays provide motorists with more accurate and specific data. As a result, drivers get more granular, useful information.

Using generalized, community-driven data, drivers might see a message stating “15 minutes to work zone” whereas on an AWP-connected portable message board at the same point, the display might show 12 or 13 minutes to the work zone. The difference is more than just simple math of two or three minutes, said Christ Pederson,

Managing Driver Expectations

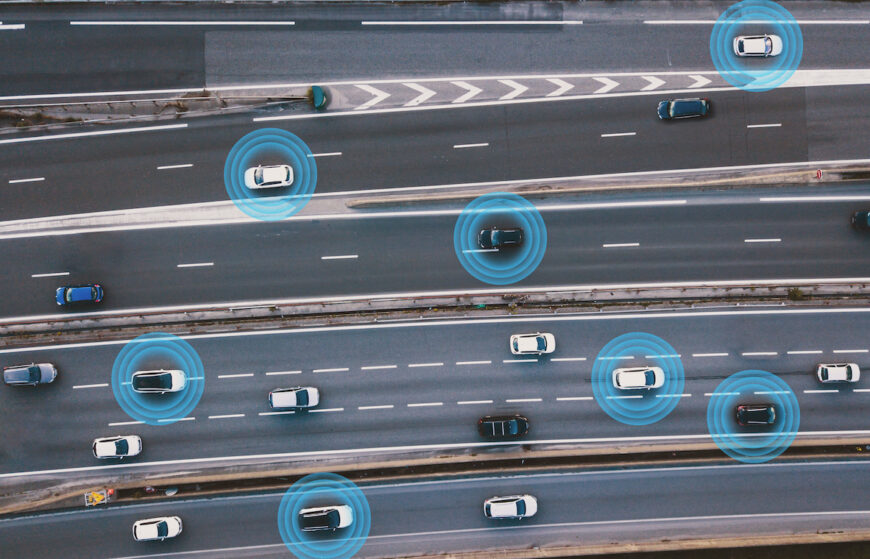

“The informed motorist is a much better driver, and less apt to erratic behavior and road rage,” Pederson said. Different types of sensors used throughout work zones measure things like speed, volume, and occupancy of vehicles. Sharing information with drivers is just one way of managing driver expectations, reducing accidents, and limiting driver frustration, he added.

“On the user end, we spend a lot of time in the education process, ensuring the specific location and placement of the sensors,” said David Gorman, AWP’s Director of Estimating in Bryan, TX.

In the I-10 expansion and the IH-35 corridor, as in every connected work zone, Pederson noted, “the goal is always reducing incidents and fatalities in the workplace.” Employing smart work zone technology, helping to educate road contractors, and ensuring that all workers are highly trained in the use of highway safety products and road safety equipment are all necessary to successful projects.

Each project starts with an evaluation process to determine the best mix of tools and sensors. Often, AWP engineers are involved in the advanced planning process alongside DOT designers and engineers, years before the project impacts the motoring public.

Find out how AWP’s experienced consulting services team can help with your next project.